NRC's Manufacturing Technologies Group makes pitch for increase in base funding with new five-year strategic plan

The National Research Council (NRC) has unveiled an aggressive new strategy to use its technological expertise to help close the gap between the Canadian manufacturing industry and its chief competitors. But the plan requires an increase in base funding to lever additional resources from other players in the sector, and is dependent upon convincing the federal government to loosen the purse strings of government laboratories.

Entitled Manufacturing Innovation: An Impact Strategy for 2000-2005, the strategy's success would see the combined budgets of the four institutes within the NRC's Manufacturing Technologies Group (MTG) (see box at right) increase from $38 million to $43 million. But a far greater portion of that base funding would be devoted to collaborative research, levering $10 million in external funding in the first year, and rising to $20 million by 2005 for an annual total of $78 million.

Noting that growth in knowledge-based manufacturing and labour productivity in Canada are seriously lagging behind many other G7 nations, the strategy proposes four new elements to the MTG (see chart below), essentially transforming the way in which the and institutes conduct business. If implemented, the NRC's vast computational and information technology resources would be marshalled to allow manufacturing firms to simulate environments for evaluating new concepts and designs, as well as developing an electronic infrastructure to connect the various innovation players in the manufacturing sector.

|

The strategy is built upon the principles of sound S&T management, horizontal initiatives internal and external to the NRC, industry priorities, and technological excellence in each of the four institutes. Among its five-year action items is the start-up or successful growth of 60 companies.

"We need to reach out to new ways of doing things. The NRC model is to stress the national institution and fill in the gaps in Canada's innovation structure, but we also have a regional thrust," says Dr Peter Hackett, NRC's VP research and technology development. "This sets up a tension but it allows us to work in local communities and work together nationally."

Despite lower productivity and a weak track record for technology adoption, Canadian manufacturing is doing quite well financially. But Hackett warns that all could change current favourable macroeconomic conditions in its favour take a downturn." The boogeyman right now is the 76 cent dollar, but what if it goes to 80 cents?"

"Canada can no longer compete on the basis of cheap labor or a low dollar, but rather on the basis of innovation. Companies that thrive in this new environment will be those that capitalize on knowledge and agility as a source of competitive advantage." — MTG Strategy |

Under the goal of advancing key technologies for Canadian industry, the strategy proposes two initiatives for virtual manufacturing and nanotechnology, stressing innovative materials, advanced processes and modeling and simulation. It contends that adoption of virtual manufacturing practices will dramatically accelerate the pace of R&D by slashing product development time. Using model-based computational simulation, real-time process information, 3D visualization tools, and high-performance distributed (web-based) environments, the NRC and its partners would work to implement virtual manufacturing techniques throughout the manufacturing sector.

|

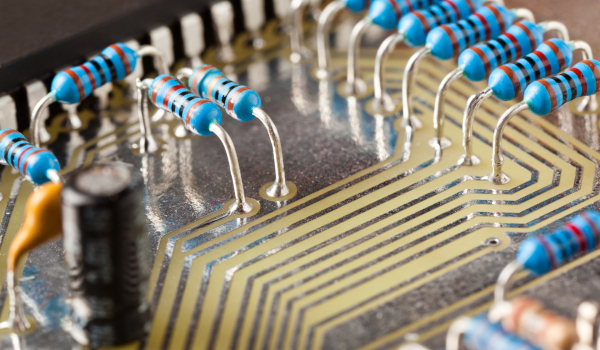

Nanotechnology is already established in microelectronics, catalysis and sensor development, but its adoption by manufacturers would allow for the development of new materials, products and processes with improved performance and functionality. Essentially involving design and production technologies at the molecular scale, nanotechnology in manufacturing is considered essential in achieving higher quality results at lower costs while meeting increasingly stringent environmental standards.

The strategy also proposed new initiatives to establish business and innovation systems for manufacturing. The creation of an industry-led manufacturing innovation forum is being positioned to facilitate a better flow of knowledge, as well as a place to exchange information and knowledge at the national and international levels. Forum participants could also make use of an integrated manufacturing technology roadmap, (which NRC is discussing with Industry Canada), and create opportunities for technology adoption and company formation.

Even more ambitious is an electronic infrastructure connecting the manufacturing community. The NRC has already registered as a proposed vertically integrated technol-ogy-to-manufacturing stakeholder site built around core competencies within the MTG. It is being positioned as an innovation enabler and a source of codified knowledge for use by MTG researchers, staff, collaborators and clients, enabling the delivery of core technologies.

|

Hackett stresses that much of the new funding required to implement the strategy will not be controlled by the NRC, although it will retain a leadership role.

"We have not stepped away from the essence of the NRC which is its strong research base," he says. "We're coming up with worthy initiatives to attract additional resources."

R$

Events For Leaders in

Science, Tech, Innovation, and Policy

Discuss and learn from those in the know at our virtual and in-person events.

See Upcoming Events

You have 0 free articles remaining.

Don't miss out - start your free trial today.

Start your FREE trial Already a member? Log in

By using this website, you agree to our use of cookies. We use cookies to provide you with a great experience and to help our website run effectively in accordance with our Privacy Policy and Terms of Service.